Making an Impact—Literally

Michaela Kane

Whether they are using crash test dummies or molasses and foam, students in class Fundamentals of Biomaterials and Biomechanics learn how to measure an impact

“Some of the students choose to use materials that are…unexpected,” Jason Luck explained, as he watched a student pour a bottle of molasses over a bowl packed with foam. Another student stood at the ready, holding a small weight above.

“Some of the students choose to use materials that are…unexpected,” Jason Luck explained, as he watched a student pour a bottle of molasses over a bowl packed with foam. Another student stood at the ready, holding a small weight above.

When released, the weight falls down the pole and collides with the syrupy concoction. If the students did their job well, the molasses and foam significantly cushion and limit the impact of the weight. If they didn’t, then the sensor attached to the weight let everyone know their failure.

The team made up of Christopher Lloyd and Ben Johns explained their reasoning a few minutes earlier when presenting their design to the other students in their 302 course: Fundamentals of Biomaterials and Biomechanics. Inspired by cartilage, the team reasoned that the goopy molasses and flexible foam would combine and dissipate enough energy to adequately cushion the weight.

“But we also thought it was funny, and that’s important too,” says Lloyd.

This unconventional design was just one of 13 projects tested during the annual Design Challenge, a key event in the class’s curriculum. Taught by Luck, an instructor in Duke University’s Department of Biomedical Engineering, students learn to apply the principles of materials science and mechanics to topics spanning orthopedics, injury prevention, cardiovascular mechanics, biomaterials and implant design.

The design challenge is an extra credit lesson for the class, where students have two weeks to come up with a design that will ideally cushion a 3.5 pound weight as it’s dropped from a height of almost two feet. Their design must fit in a circular basin at the base of a metal pole, which guides the weight. An accelerometer attached to the weight measures its deceleration after impacting the students’ ‘cushion.’

That reading is then used to calculate the HIC, or Head Injury Criterion, of their design. The HIC measures the likelihood of a head injury occurring from an impact. While it’s traditionally used to test the safety of objects like helmets and cars, students use it to determine who made the most effective––and safest–– design, aiming for a HIC smaller than 88.

“If the mass just hit the lab floor, the acceleration would be very high, because the impact velocity would change to zero instantaneously. It’s a hard impact,” explains Luck. “With this project, students need to leverage everything they’ve learned in class to create a design that will minimize the HIC to a level that will prevent an injury.”

Students run their test three times, averaging their HICs to calculate their score. While this number is used to identify a winning team, students also measure the coefficient of variation, or how similar each HIC was from the three trials. Ideally, the HIC scores will be similar to show that the design wasn’t a fluke and could consistently work well.

Students run their test three times, averaging their HICs to calculate their score. While this number is used to identify a winning team, students also measure the coefficient of variation, or how similar each HIC was from the three trials. Ideally, the HIC scores will be similar to show that the design wasn’t a fluke and could consistently work well.

“I think it’s really important not to parachute in on topics and then leave them immediately,” says Luck. “Sometimes they don’t see the connections between what we introduce in a lecture setting and what projects they pursue, so in this class we really try to foster these connections with intentionality by developing learning arcs that begin with exploration and fundamental principles, transition to hands-on laboratory experiences, and build to student-driven applied experiences. The hope is that our students will see how everything is connected from the lesson to the practical experience.”

“Everything you learn in class complements this project in a really practical way,” says Julie Mandimitsira, a junior in BME, who worked on the project “Flirtations with Death”. “This was a great experiment because we were able to apply the theoretical principals to reality in our own way.”

While other teams like “Monkey Trap” and “Best Thing Since Sliced Bread!” also opted to use food like pieces of banana and baguettes to cushion their weights, other teams opted for inedible measures, like crumpled up paper balls or taped rings of map paper. “Another HIC in the Wall” used folded newspapers, reasoning the thicker paper would crumple like the front of a car in a collision and soften the landing. And the team “Impact Factor” decided on using a single coffee sleeve from the Wilkinson Building’s Coffee Shop when they found that the last-minute test worked better than their previous designs.

While other teams like “Monkey Trap” and “Best Thing Since Sliced Bread!” also opted to use food like pieces of banana and baguettes to cushion their weights, other teams opted for inedible measures, like crumpled up paper balls or taped rings of map paper. “Another HIC in the Wall” used folded newspapers, reasoning the thicker paper would crumple like the front of a car in a collision and soften the landing. And the team “Impact Factor” decided on using a single coffee sleeve from the Wilkinson Building’s Coffee Shop when they found that the last-minute test worked better than their previous designs.

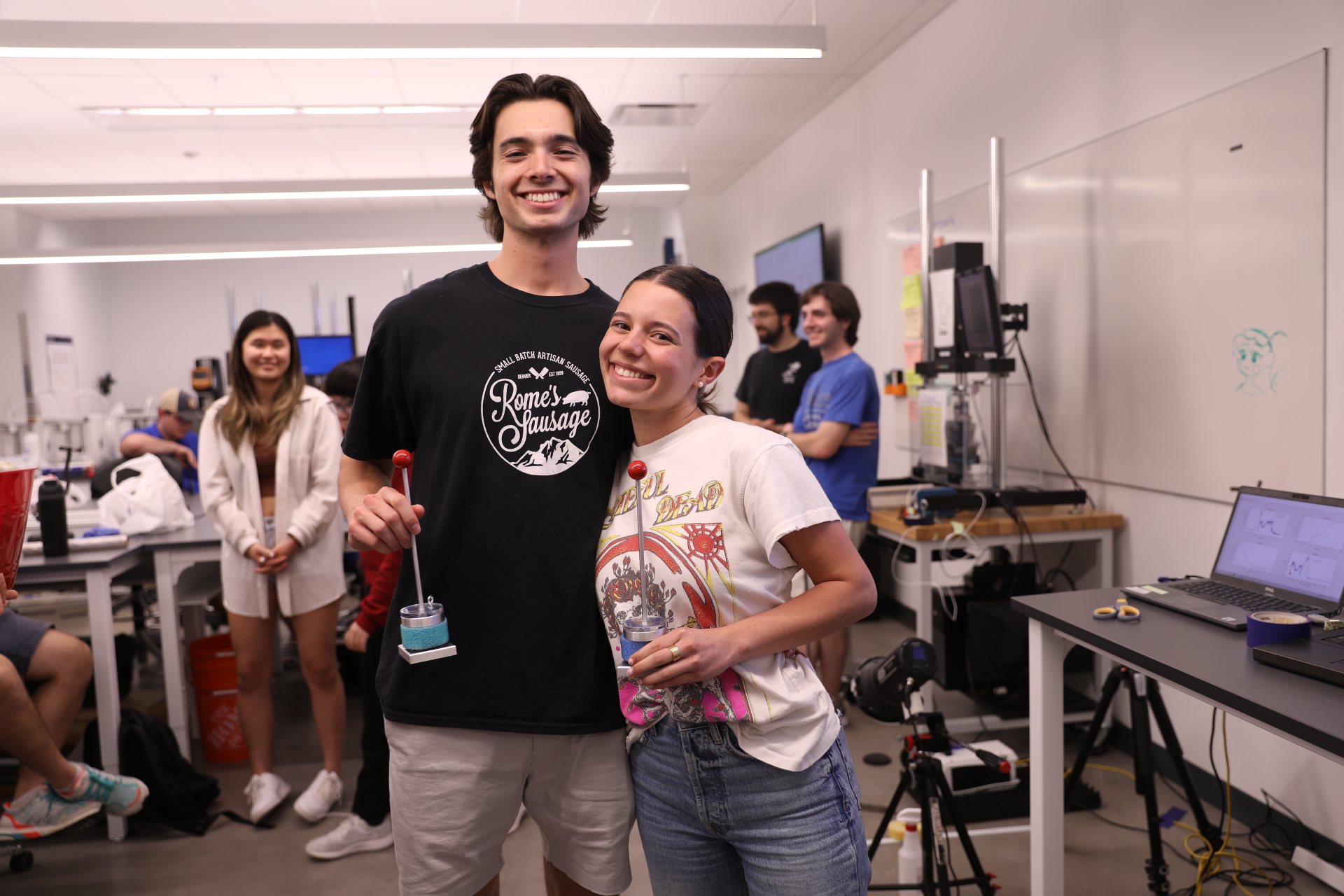

Ultimately, Adrianna Diaz and her teammate Tas Miley prevailed with an average HIC of 30.91 for their team “Luck of the Drop,” which involved creating two cylinders out of toilet paper rolls and newspaper.

This experiment, Luck says, helps the students think about the types of materials that are used to create helmets and other protective head gear, leading directly into a final experiment, which Luck calls BIAT, or ‘Bringing It All Together.’

This experiment, Luck says, helps the students think about the types of materials that are used to create helmets and other protective head gear, leading directly into a final experiment, which Luck calls BIAT, or ‘Bringing It All Together.’

Students don’t know what they’ll be doing until they enter the lab, but the previous day, Luck asked them to think about two key questions: Why would you have your six-year-old wear a football helmet while playing football instead of a bicycle helmet, and why would you have your six-year-old wear a bicycle helmet while riding their bike instead of a football helmet?

“We actually plant the seeds for this question on the first day of class, when we leave football helmets, bike helmets and crash test dummy heads on all the tables, and I ask them to think about how biomechanics relates to these objects,” explains Luck. “On the last day of the semester, I ask them that question again, but this time they should be able to identify and explain how football helmets are made to withstand multiple impacts while bike helmets are designed for a single, high impact.”

For their final experience in the class, students design an experiment that attempts to validate those key points. Students use the same setup to drop a crash test dummy head in bicycle helmets and football helmets to examine the different impacts—and ideally prove their hypothesis.

“My approach and objective for this course is to help our students see the connectivity between the lessons from the beginning of the course all the way to the end of our journey,” says Luck. “Ideally, by the end, they’ll be more confident in their knowledge and abilities and more empowered to take that next step, where I can just stand back and watch them confidently work the problem and know that they are ready for whatever I throw at them next.”