What’s the point?

Go boxes exist across for a spectrum of purposes. Perhaps you have a sewing box, or a toolbox, or a box with everything required for D&D. By doing this, you have everything needed for that particular task and can be ready to go within a few moments notice – or not have to get everything collected for Friday’s game and you’re already late. Building a ham radio go box is no different – you can grab the unit, head out the door and and once on site have everything you need to operate.

I am primarily a portable operator (as a result of my HOA) who must set up each and every time. With a go box, having all my radios are mounted in a single portable box with the radio gear and power connections set up means I will have much longer to operate – and that much more isn’t left to chance.

I was inspired to build my go-box after joining the Ham Radio Go Box group on facebook. I ended up throwing my new 2m mobile in there as well as a result of starting to run my club’s monday night net. Here are pictures and remarks of the process.

What’s in the Box

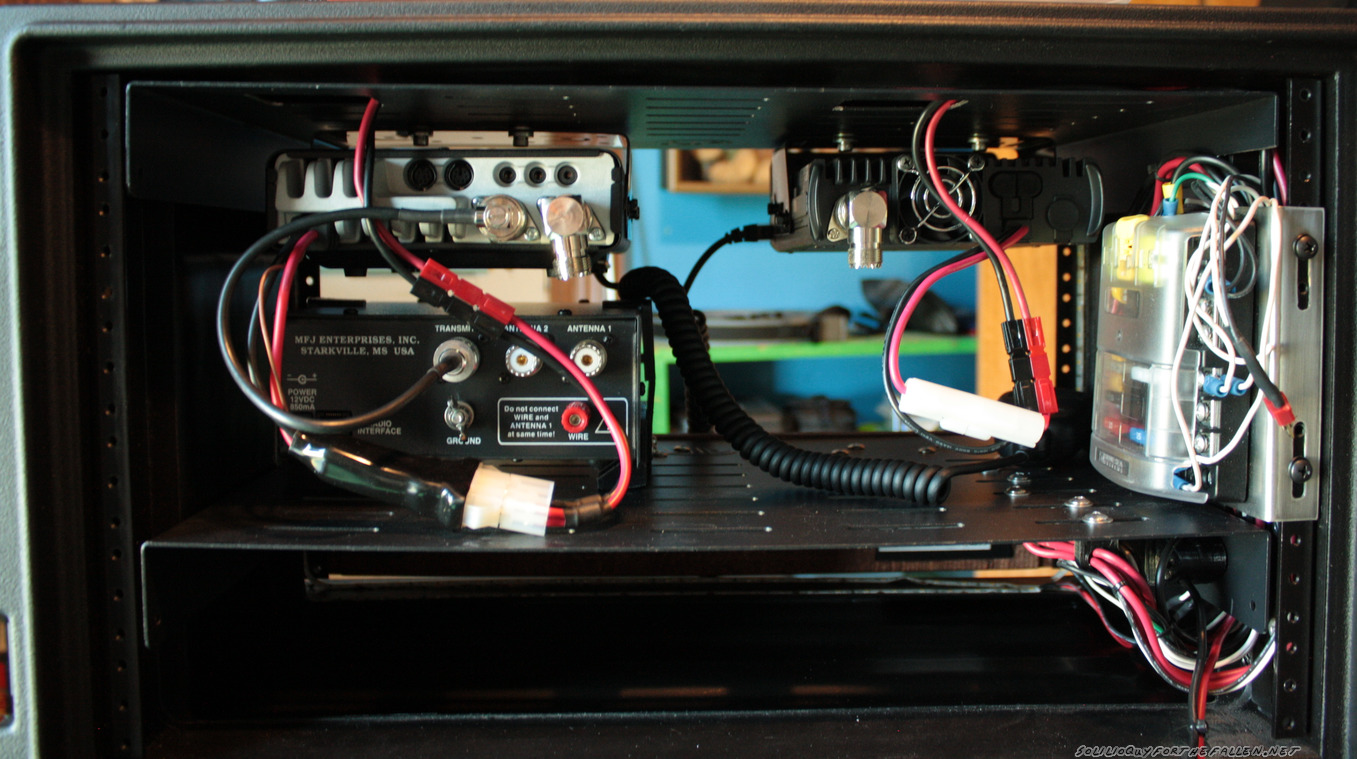

Check out the for pictures. In the go-box, I have

- HF + 2M/440 by the Yaesu 857d

- MFJ 929 HF tuner connected to the Yaesu

- 2m/440 + Crossbanding from the Alinco DR-735t

- Built in illumination for dusk or after operations

- Built in cooling for both radios

- Onboard 120V power conversion and a power monitoring system for amp load and voltage (voltage is monitored on battery power)

- USB Phone charging

Build Log

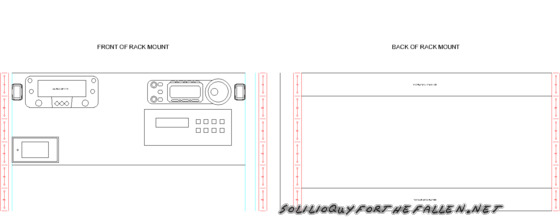

I drew an initial layout in cad to determine if I should purchase a 4u or 6u rackmount case. The rackmount system comes from the portable audio world and specifies a certain amount of space and a mounting system. Trying different variations, it was decided that a 6u box would provide for all the equipment I had currently, and some future expansion. I decided that purchasing a commercial rackmount would give me better results then building my own box as I have seen some do.

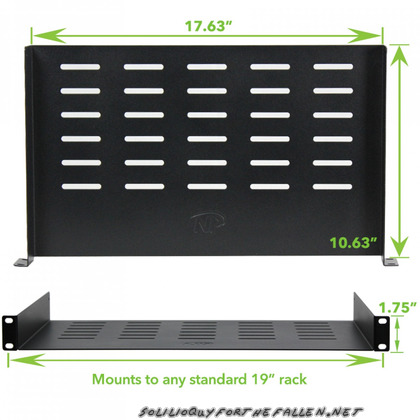

Ultimately, I selected the SKB 6U Roto Shallow Rack unit over a comparable Gator Box (or eurolite) for two reasons. The first was that the SKB features an internal gasket that while it won’t make the water proof, will certainly help keep out the spirit dampening rain storm. The second was that the SKB was better reviewed then any other rack mounts I had found. The additional sturdiness of the unit was worth the additional expense. I avoided the particle board solutions by Eurolite & Musician’s Friend due to the weight. Both the wood and plastic boxes are flight rated so there should be negligible difference in their durability with the weight of the poly boxes being at least half the weight of their wood equivalent. Radios & other things will make the box heavy enough on their own. Then, I needed to go from the vertical pillars of the rackmount system to a horizontal surface to mount the radios, tuner, and other gear. To rack them into the go-box, I ordered 1u racks from Navepoint. By ordering directly from Navepoint I saved about $2 each rack, exchanged an email for another $5 off, and still had free shipping. Much cheaper then purchasing from Amazon

I used the mounting brackets provided by yaesu and alinco for their radios. No reason to reinvent the wheel for a custom solution when what was provided works well. The radios were mounted in the slots in the navepoint shelves with the brackets that came with the radios from their manufacturers. You’ll note that at times the radio shelf is clamped a small masterforce vise. This method of keeping the shelf vertical to work on it works fairly well, especially when you let gravity work to your advantage. This is my go to method for handling the shelf when it is outside of the box.

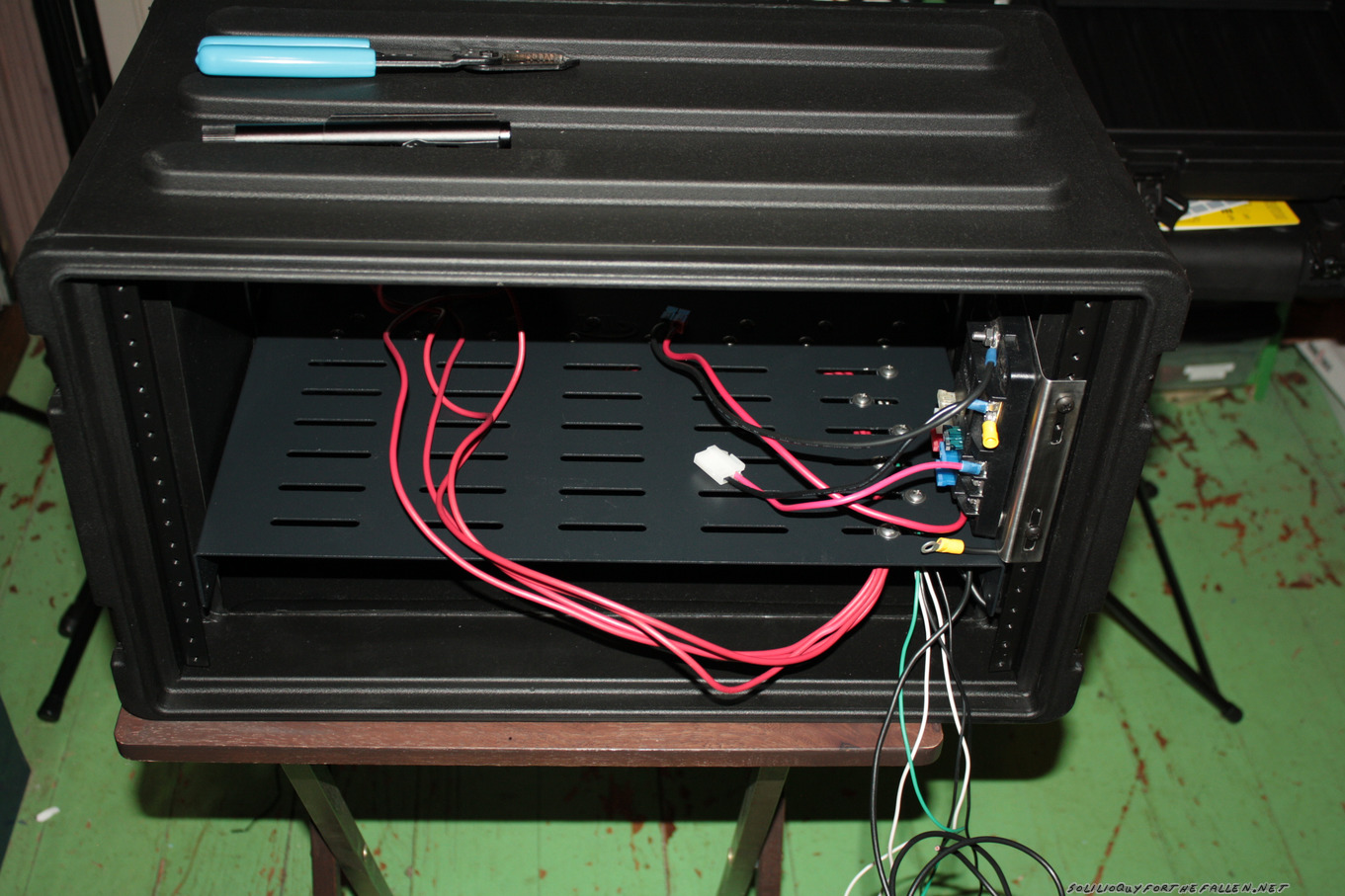

A Blue Sea Systems 6 Circuit With Coverwas sourced from amazon. This helps protect the radios from short circuits with fusing, as well as providing a neat and clean way of distrubuting the power from whatever source I am using. I should note that its built with metric standards. Because of this, i found it a bit difficult to work with as I have minimal metric tooling. An initial fitting was done to make sure I was on course with the space requirements of everything so far. (I apologize for the potato phone pictures.)

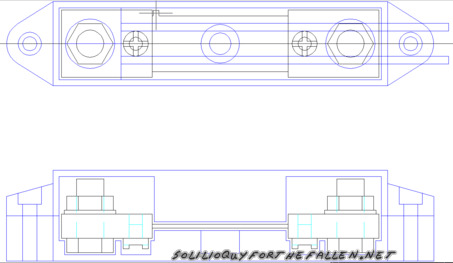

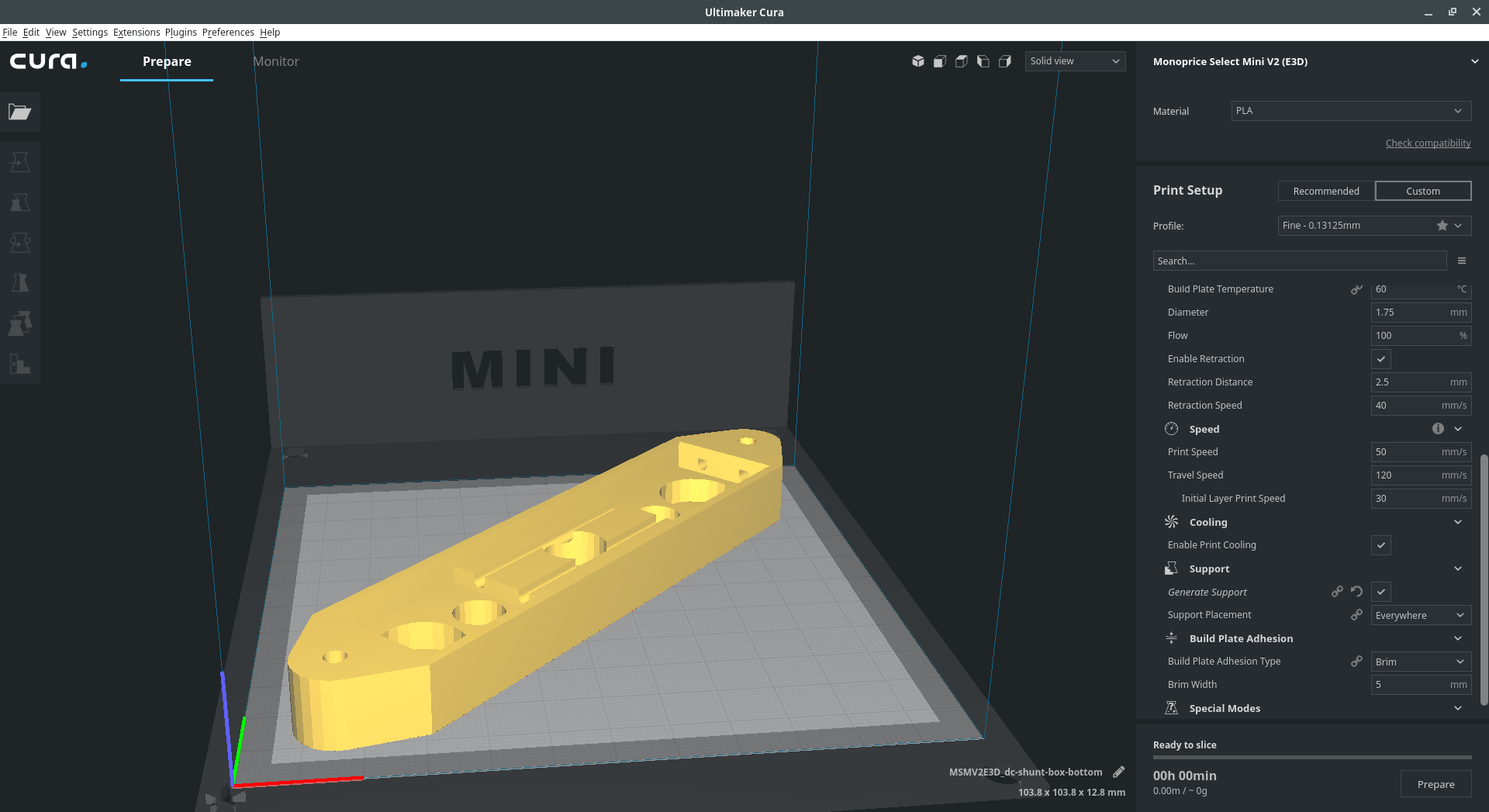

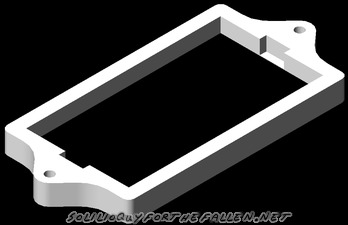

Because of my desire to run the system from a battery, I ordered DC Shunt Monitoring System from amazon. I chose this particular model as opposed to the some of the meters around for its low draw – and that I can shut of the monitor and have no draw at all. The system displays the current voltage of power system, amps in use, watts, and watt hours. I needed a way to encapsulate the shunt, so I designed and 3d printed a shunt box that would allow me to mount the shunt in any orientation. The bottom of the shunt box has two hex hole for a 6-32 nuts to press in. The top has holes for 6-32 fasteners to fit through and tighten via the 6-32 nuts. The center hole is to bolt the shunt mount on the frame with a 1/4-20 bolt. STL below. There are tunnels for the main power wires and the display relay wires.

To mount the monitoring display, the power switches, and a USB charging port, I needed a small panel about the size of a 2u panel (3 1/2″ x 19″). The layout of the switches, power display, USB Charger, and control switches was mostly laid out on the fly. After layout, cutting, and test fits the board was sanded through to 400 grit and stained. Rustoleum Spray Lacquer was used as a protective coating. I found that laying the piece out horizontally and using heavy coats resulted in the best surface finish.

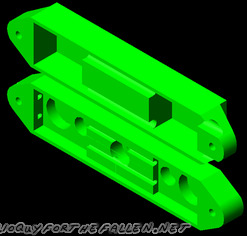

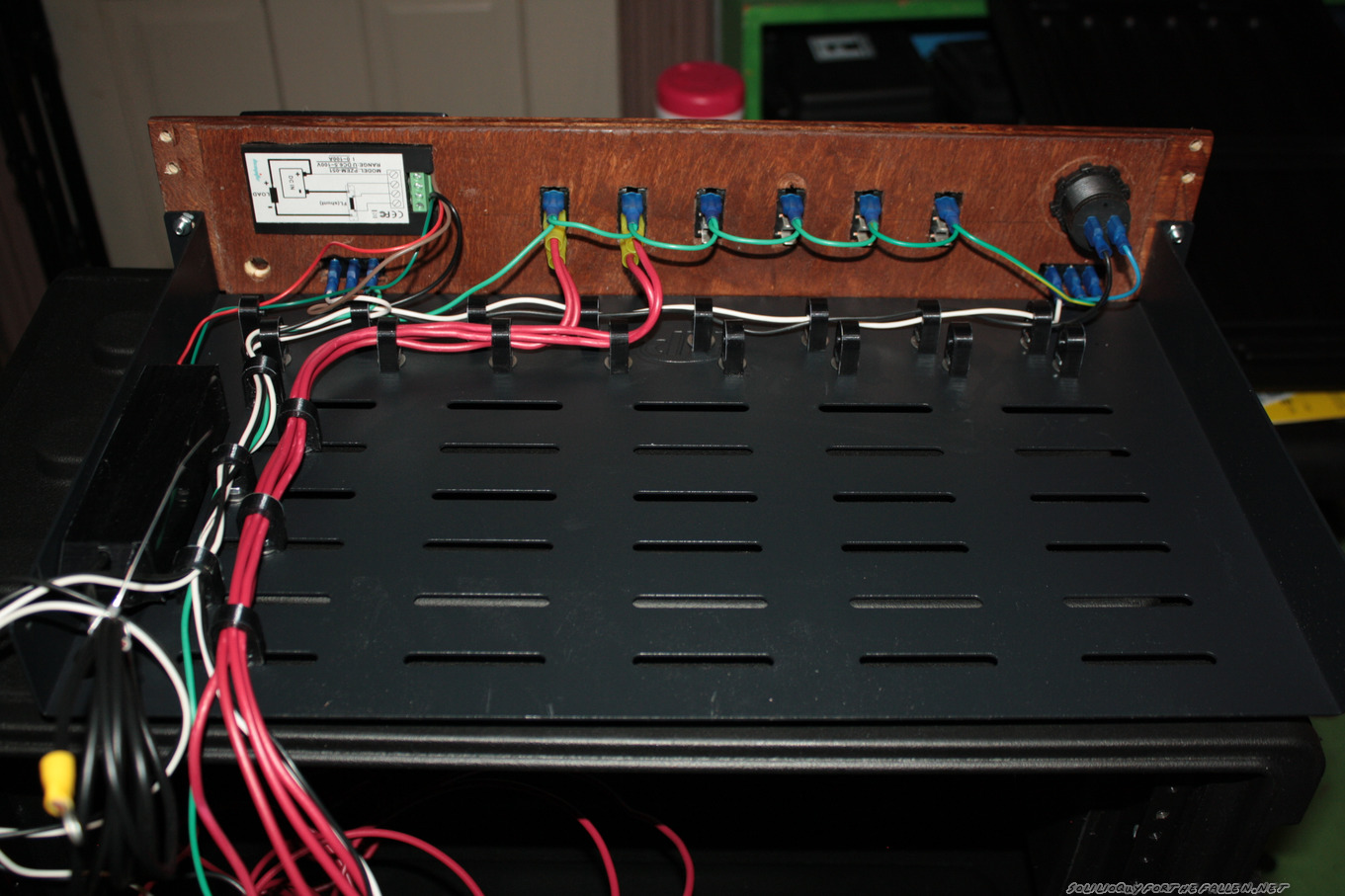

Each function of the box (such as the radios, the usb charging ports, the monitoring display) can be switched on individually. I sourced a number of 13.8 VDC 25A switches from Digikey instead of using lower amperage switches and relays – again with battery powered operation in mind. Because the switches were designed to be mounted in thin plastic, not plywood, I needed a way to engage the locking tabs on the switches on the board. Switch mounts were designed and 3d printed to engage the locking tabs on the switches and screw into the face of the board. The monitoring display was also made to be mounted in thin plastic or steel, so a frame for that was also designed and 3d-printed.

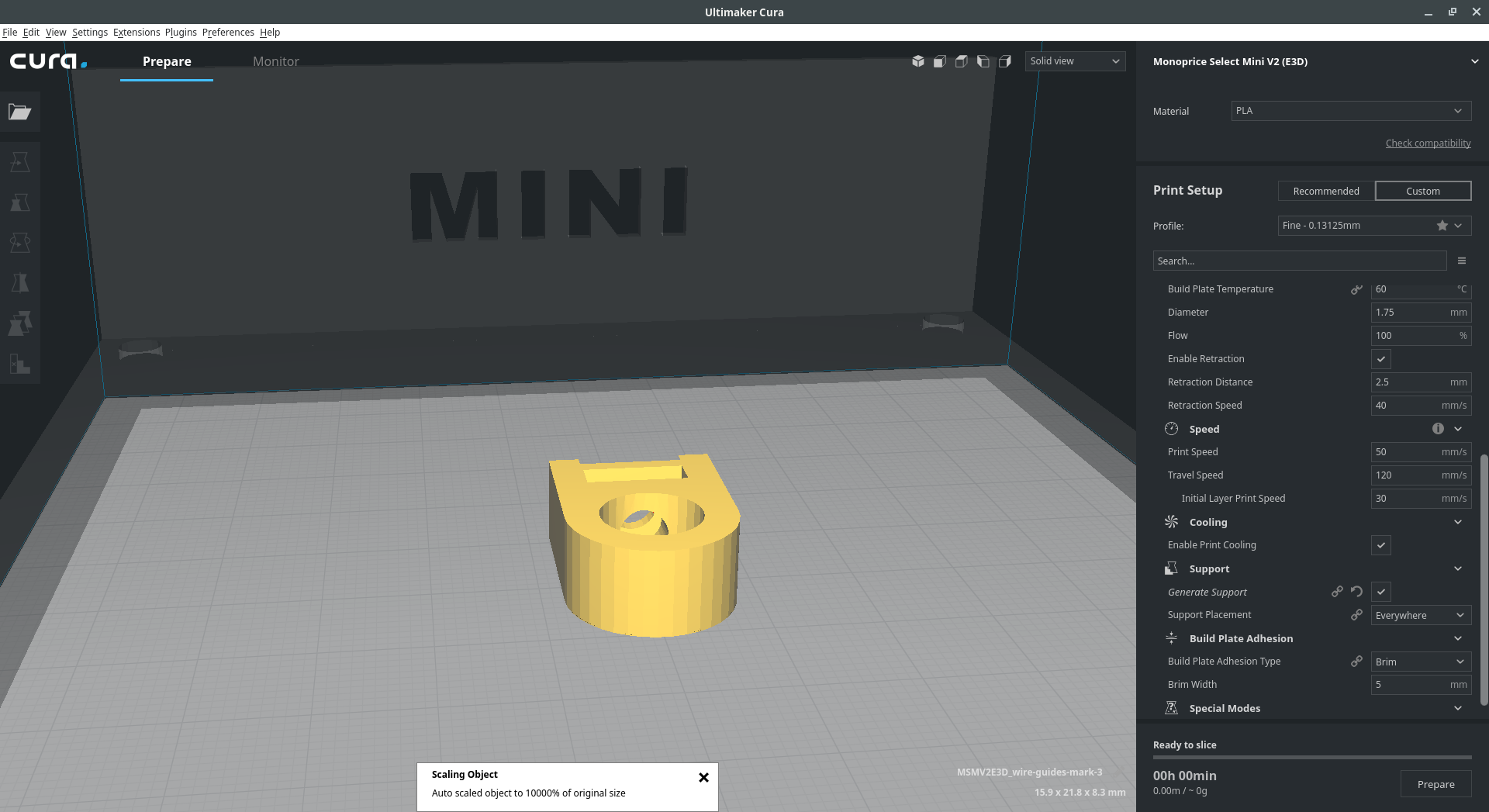

To keep the wiring neat and tidy as I run it to the switches, power supply, and more small wire mounts were designed and printed with my monoprice. An 8-32 nut is pressed into the slot, a #10 fender washer is placed in the top, and then it is bolted onto the tray with a 8-32 x 7/16″ machine screw for wires to run through. This helps keep the wiring tidy and supported.

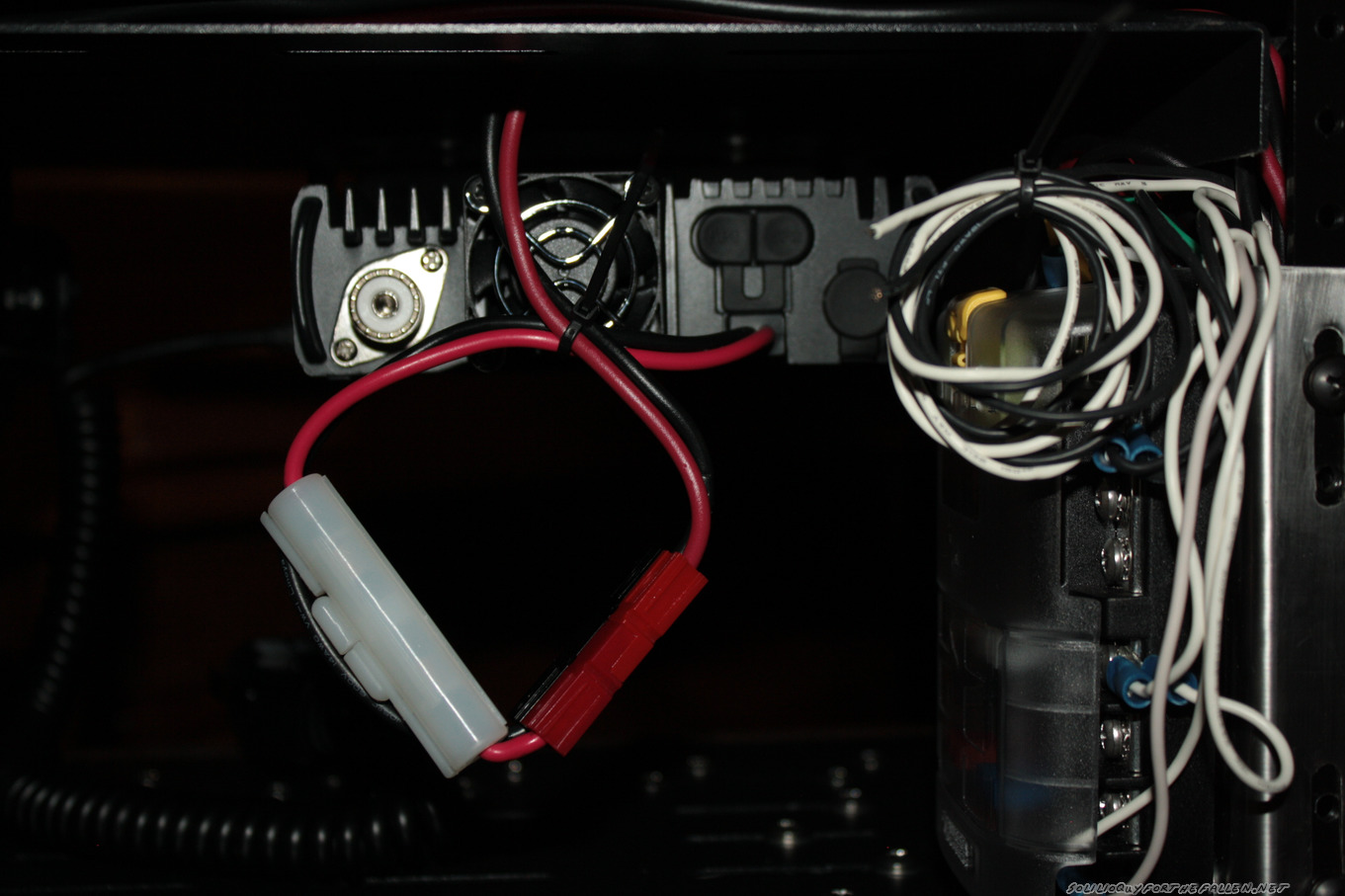

Adding a feature I probably don’t need, stick-on LED tape was installed around front of the box. First the surface is prepped with isopropyl alcohol and then allowed to dry. The LED tape is applied, leaving the power leads in a supposedly convenient position. Deans Connectors were ordered to allow me to connect the switching panel to the LED tape. With these connectors installed, it becomes trivial to disconnect the lights from the switch board. High quality adhesive shrink tube was applied over the solder joints to protect against shorts.

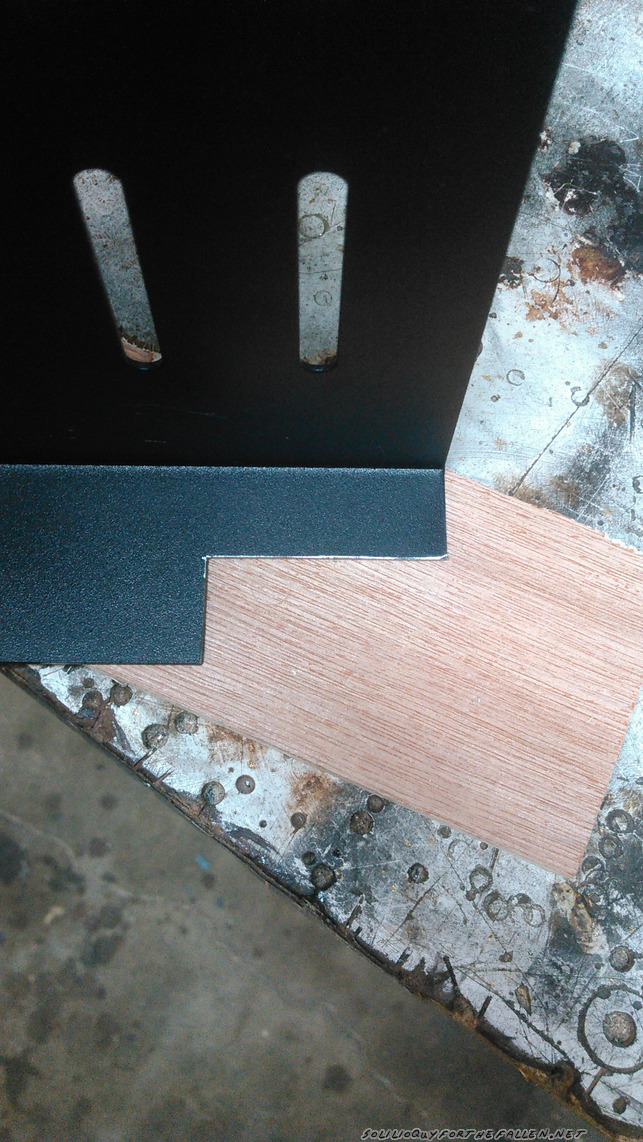

After this, I began the final fit up and cable management of the wiring inside the case. This was fussy, test, trim, retest, retrim, crimp, retrim, install, remove work that consumed the better part of four days of work. Cable management is an important part of any job and I didn’t want wires hanging in loose bundles looking like garbage – hence printing and installing the wire mounts. Here you can just see the power feeds for the radio fitted over the top of the shelf. They are then fed down through the slots in the trays to each radio. Later, I realized that I needed to open up the slots as an powerpole can’t be pulled back through. Two of the ventilation slots were cut to form a generous slot to pass the powerpoles through. These were cut with a dremel, and then some hand filing to clean up the holes. I also needed to remove a section of the top rack on the side so that wires could pass out from behind the distribution box and make the required connections. Again, this was cut with a dremel and then hand filed.

I had to decide how to hook up the radios – whether I was going to use the factory connectors or powerpoles. I ended up with a mix of the two. I removed the alinco connector and switch the radio directly to Anderson Powerpoles. For my 857, I decided to keep the yaesu connector because of the brown wire (a stupid item imho but best to leave it). Powerpoles were installed on the drops, then a generous coating of dielectric grease was applied. I’ve read that powerpoles corrode quickly so this will help keep them from oxidizing without damaging the ability of power to flow across the tabs.

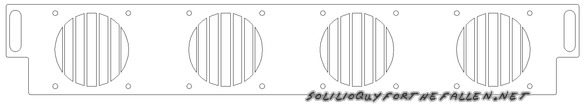

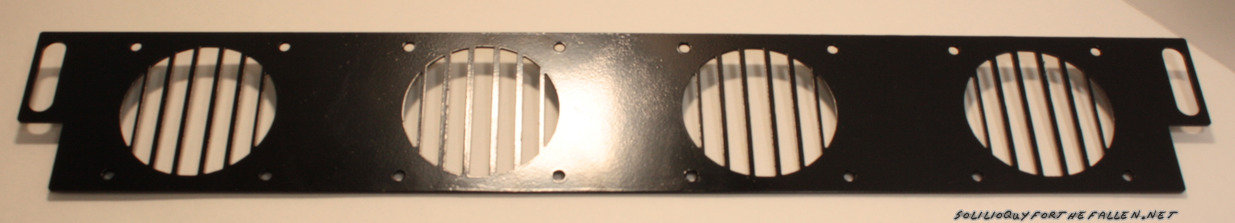

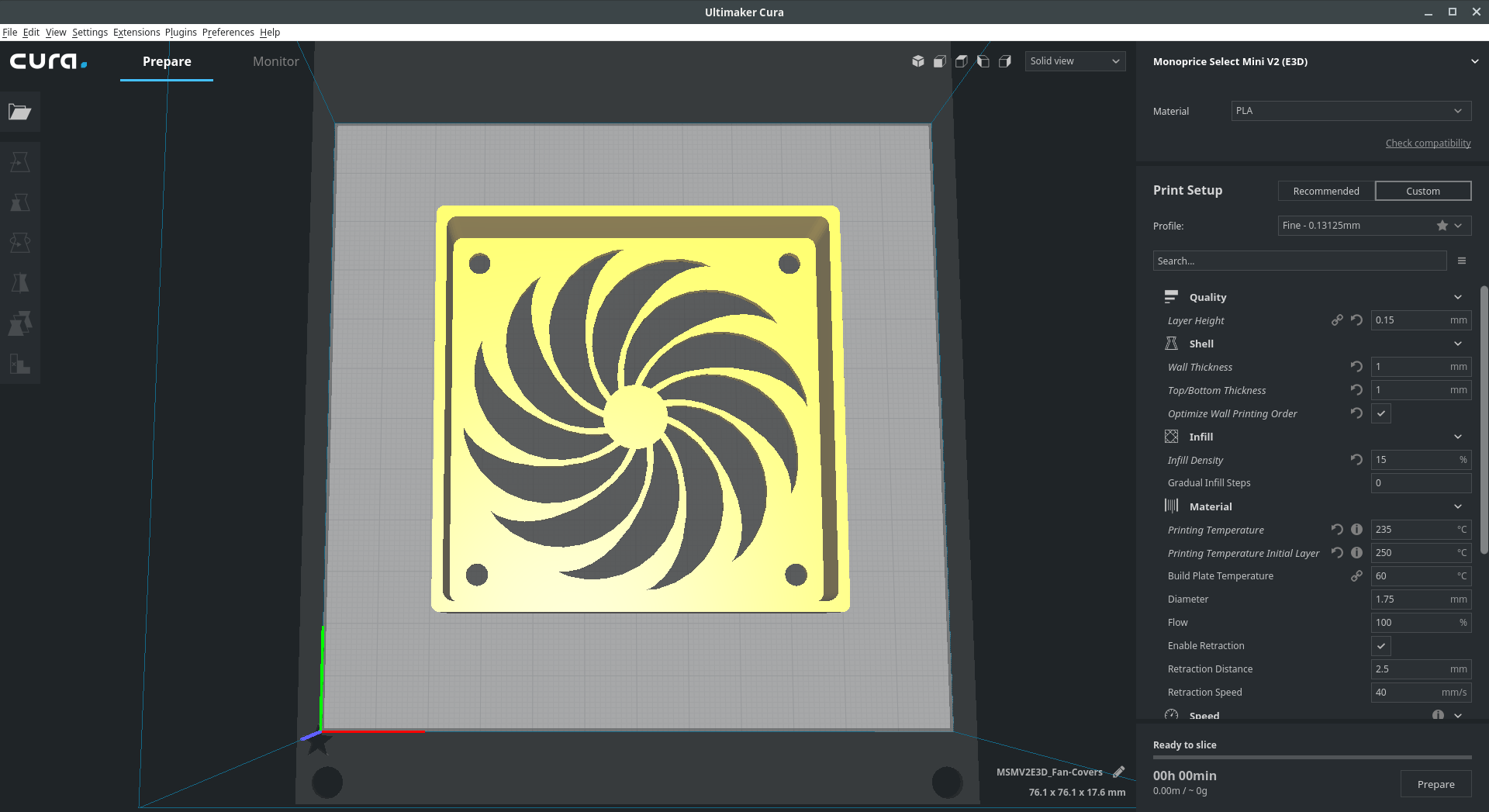

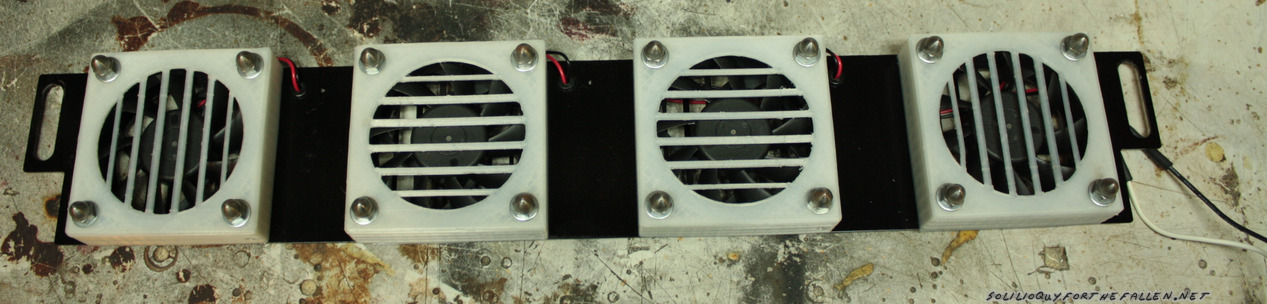

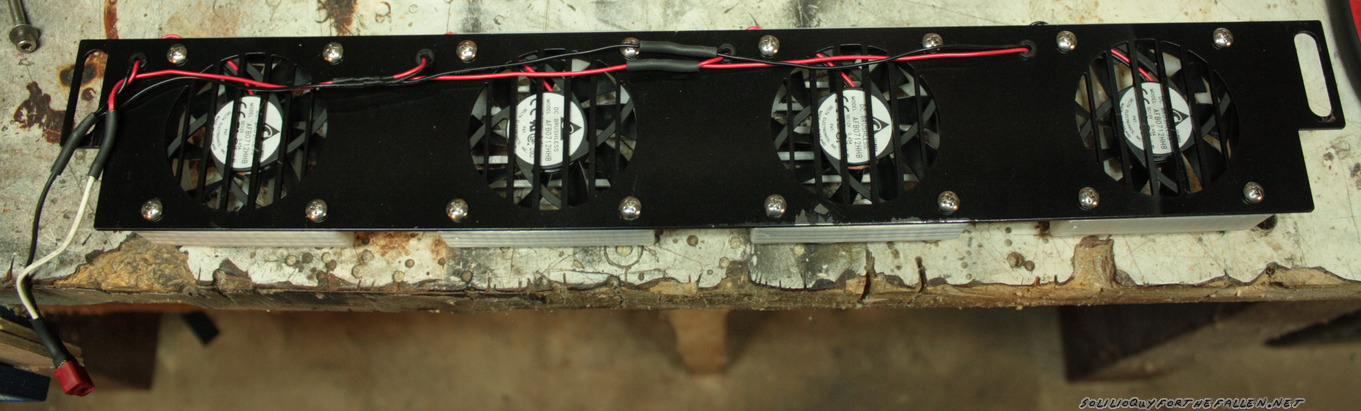

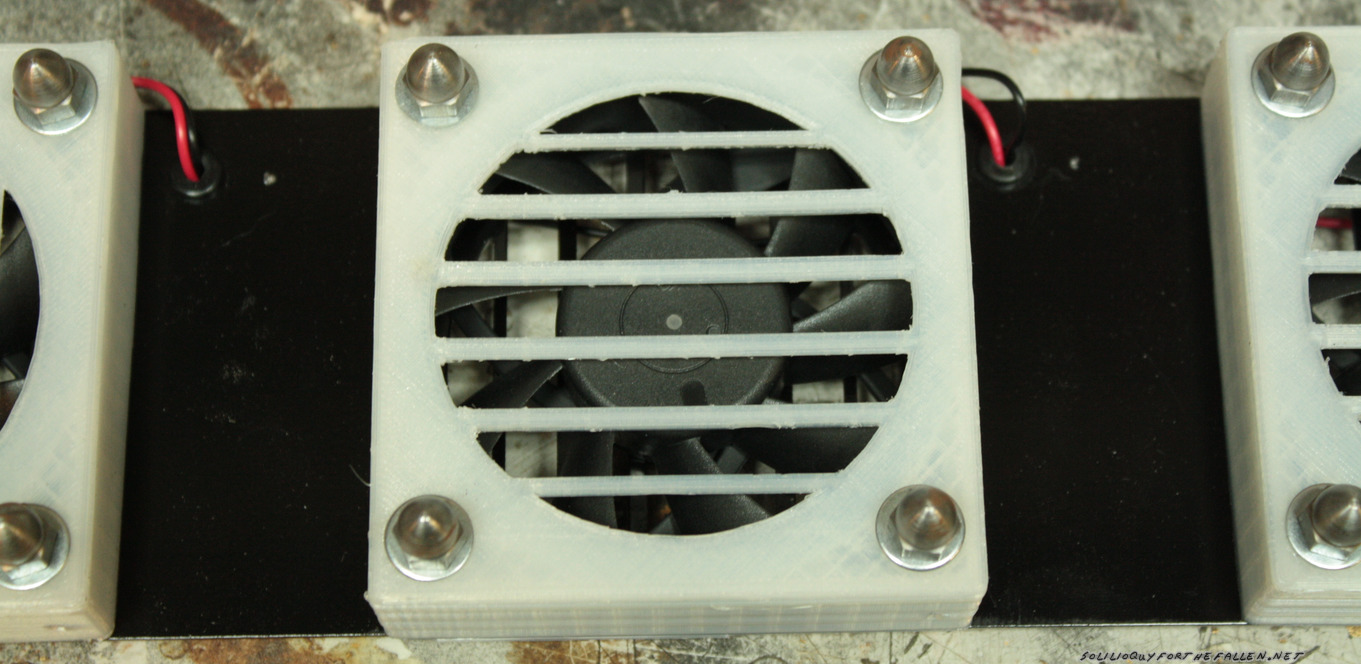

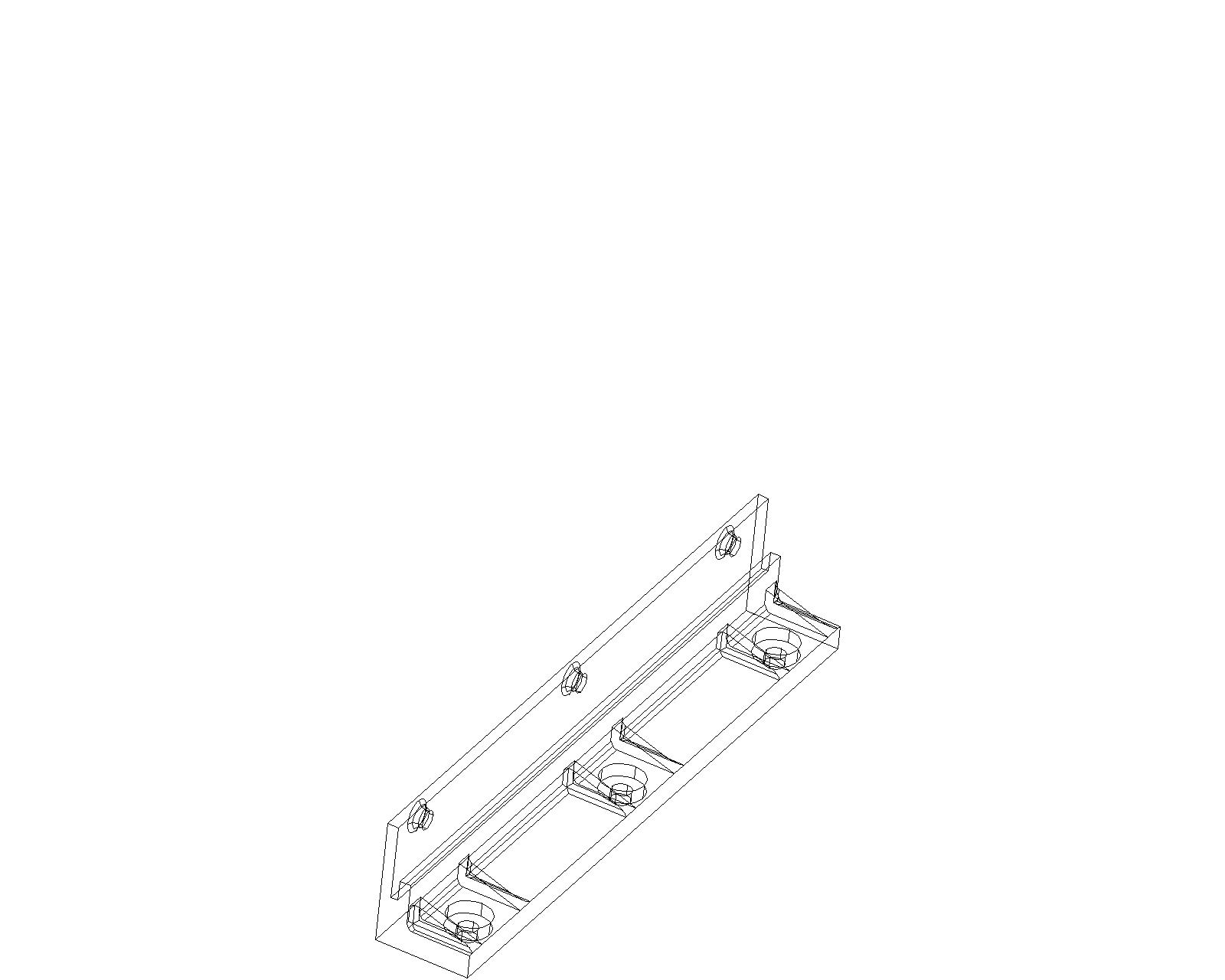

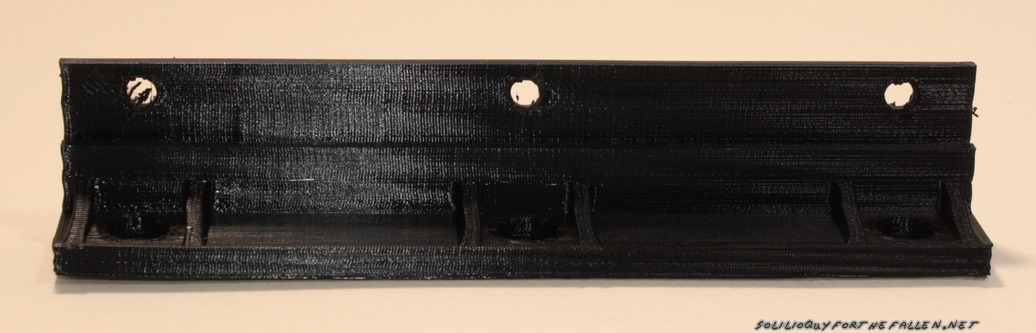

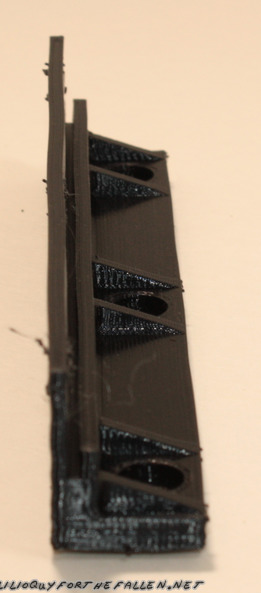

Axial fans were ordered to provide additional cooling to the radios. The fans from digikey were selected to to provide maximum airflow with a low 38.5dBA noise. If needed, I can mount a rheostat to slow the fans and lower the noise, at the cost of airflow. A fan mount was drawn in cad, and a shop favor called in for the panel to be cut with a water jet. Once it came back from the shop, a coat of rustoleum professional grade primer and then rustoleum gloss black was applied. I refuse to utilize krylon paints in my shop. I broke a fan blade just by tapping with with my finger, so I clearly needed to provide some protection to the fan blades. A fan cover mirroring the style of the grid on the fan mount was designed and printed. I reasoned that the fans could push no more air then they could pull, and mirrored the design of the fan mount. To save print time in the future, I redesigned the guards to have a sleeve and cover. While the sleeve adds slight complexity to the walls and increases their print time, it will save roughly 3 hours should I need to redesign or reprint from breakage the guard grid in the future. Here are the sleeves, and the first & second iteration of the guard. Printing with just shoulders pressing against the fan saves an hour of print time on the monoprice.

Small rubber grommets were ordered and 3/32 holes appropriate for the grommets were drilled. Grommets installed, the wires were passed through the side of the guard, and then wired in parallel to a deans connecter which was then hooked to the appropriate circuit. As will the led lighting, this makes it easier to service various parts of the box. The fans are attached with 6-32 bolts and acorn nuts for a finished look. The fans pull air from the rear of the case and push it towards the front. The user of the go-box experiences a slight breeze.

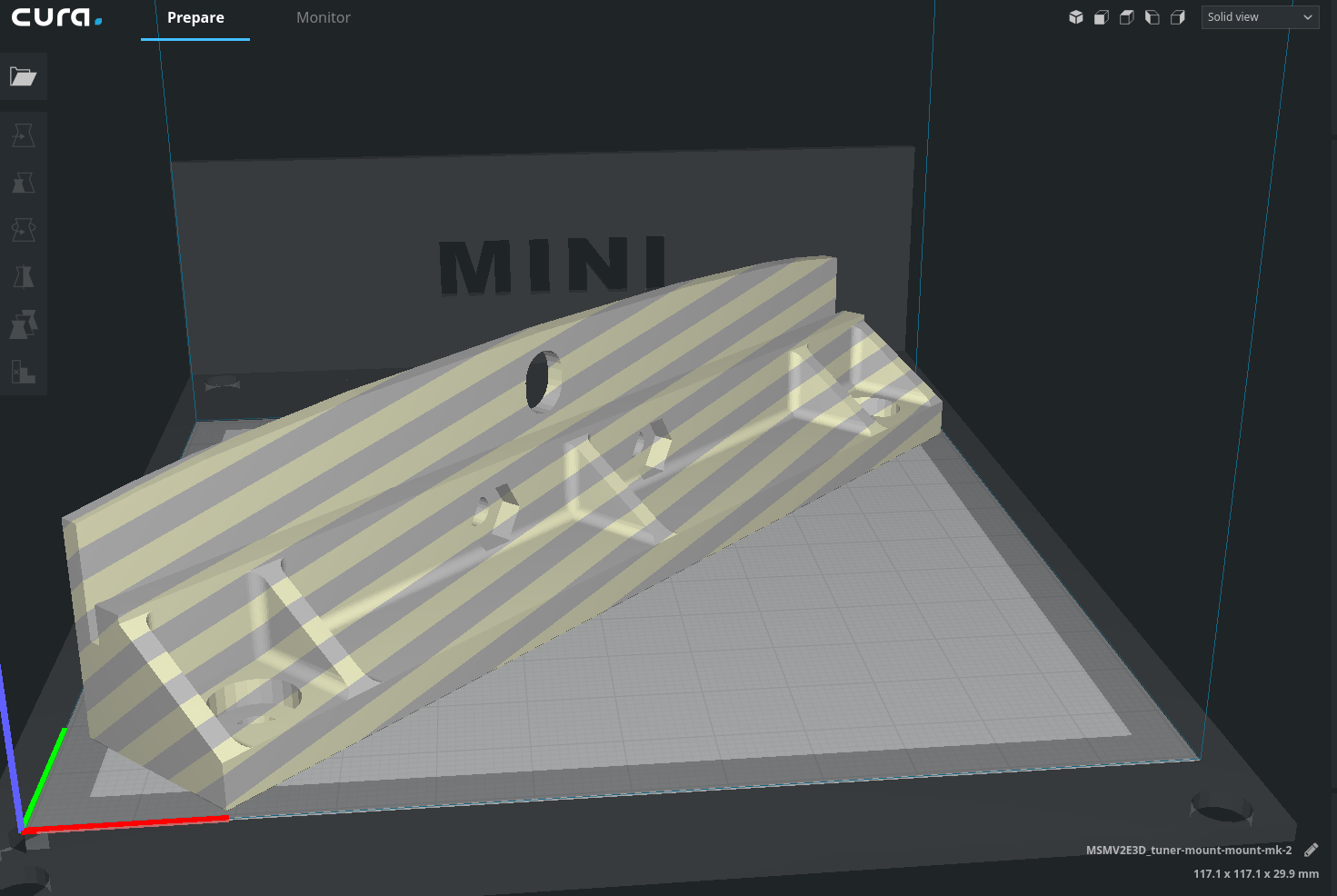

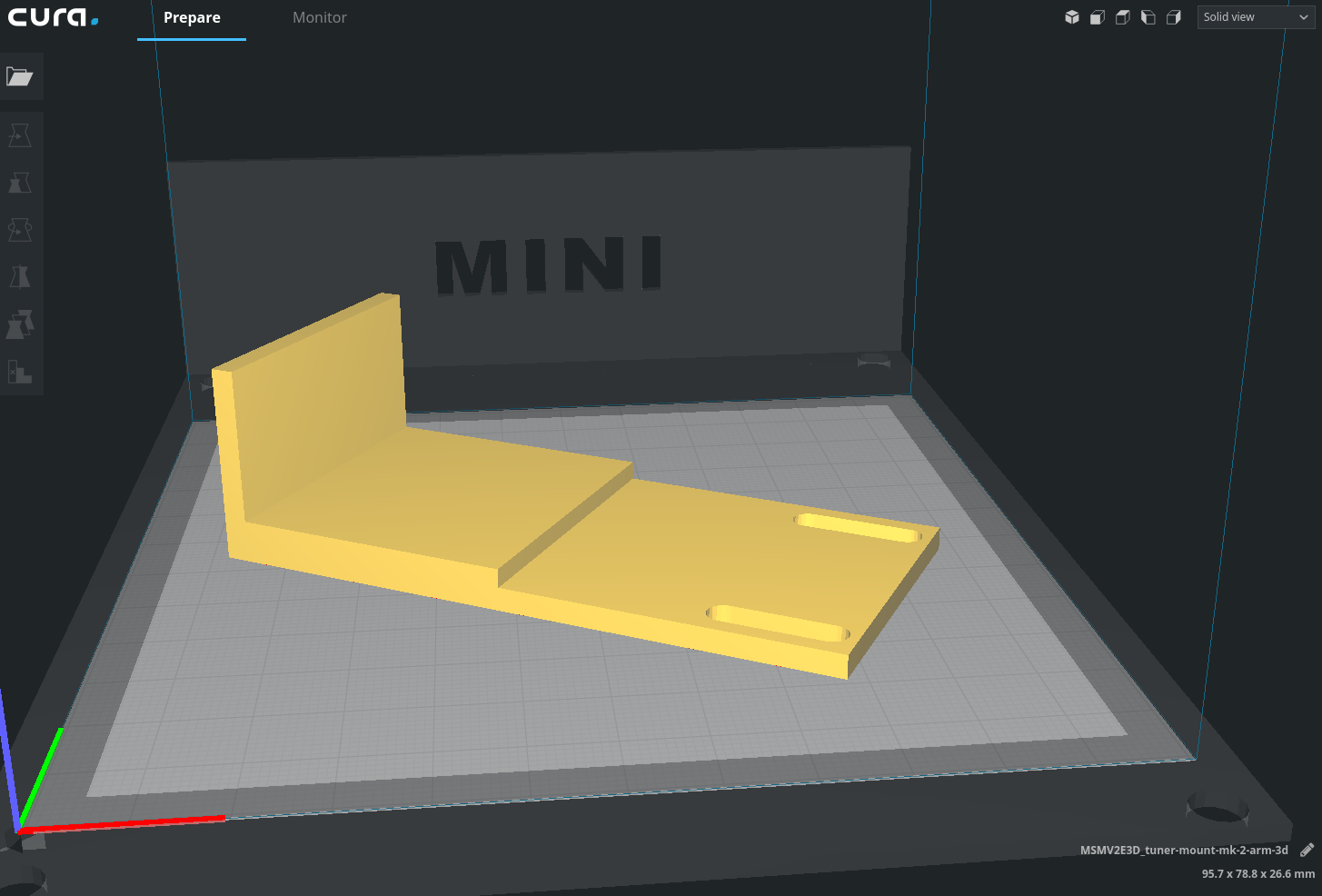

A “rack” of sorts was designed and printed for the MFJ-929 HF Tuner paired with my Yaesu 857d. This rack barely fit on my monoprice – I had to set the bed size to 121mm x 121mm and get rid of the brim to print these. Taking advantage of rapid iteration through 3d printing, here is the mark 2 version of the tuner mount mount, which loses a mounting hole on the base, and eliminated the need to drill and tap the side of my tuner as I had originally planned. A slot that fits to the center screw on the side of the tuner helps center & retain the tuner in these mounts. Then, a sliding armature was designed that will insure the vertical retention of the tuner.

With the initially printed arms, I had issues with the print warping, and the arms tilting back. I lost some faith in the retention ability of the arms because of this. I initially planned on printing the arms in a way that they couldn’t warp from heat differences as the layers were applied. I changed from the initial arm design to Mk 2.5 to help reduce the print time, and to make things look nicer. After a test print with the arm at about 15° on the print bed I decided I didn’t like the results when I cleaned up the print. So instead, I printed two more arms, gently heated the pla prints, then pressed down with a wood slat to intentionally warp the print so that when bolted onto the mounts, they would squeeze down and against the print. Mk 1 & Mk 2 below.

The fan panel makes it harder to get to the pl-259 jacks on the back of the radios. To make it easier, I ordered and installed some right angle adapters to the radios. The 857 was connected to the tuner with a cable that has a right angle connector.

Closing Thoughts

At this point, I’m posting the build log. I will have to make a few updates for things such as integral power supply, hand mic mounts, and the smaller 2M antenna I’m building to keep in the go-box for deployments. However, the go-box itself is practically done.

There are a few things I will do differently for the next build. I would have a smaller switching section. The parasitic draw of the radios is not enough to justify the cost & trouble. If I was doing a SOTA where I had to hill climb for this, I would take a Yaesu FT-817nd or Yaesu FT-818. Still, for this box I think it all works well and I am in no hurry to tear everything apart to make Mark 2. Even though this is less of a go-box and more of a shack in a box I’m satisfied with the result.

Gallery

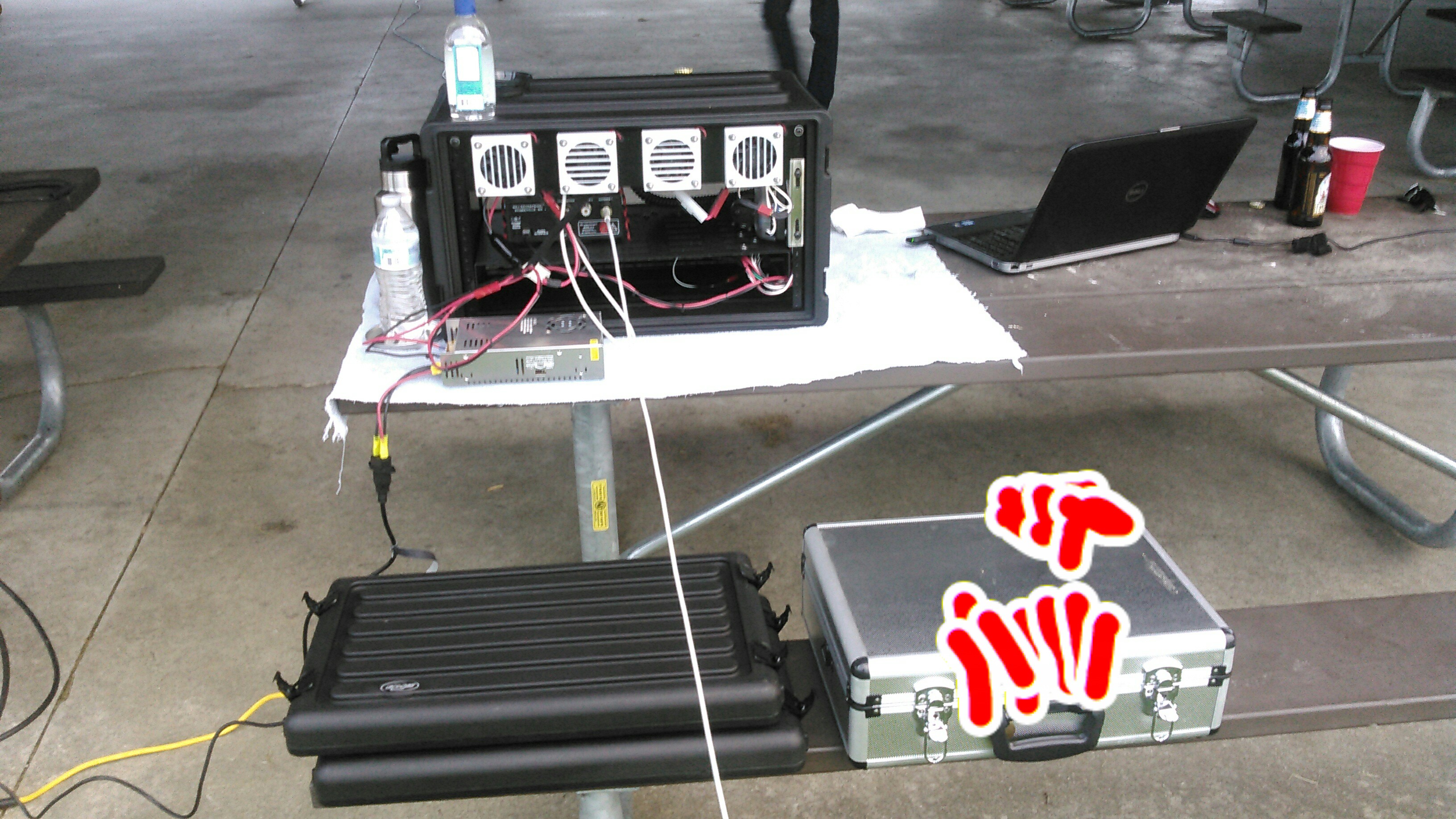

Go Box at Field Day

The go-box’s first deployment was the ARRL’s 2018 Field Day. Note that the tuner is retained by string and that the power supply is external. I simply ran out of time to get everything done.

Operated with my W4KGH End Fed Antenna (Doc 1, Doc 2) with 9:1 Unun, 55’ radiator & counterpoise. Worked well on 40M. 80M was barely able to tune. The noise floor for 80M was S5-S9 though so I was unable to hear anyone.

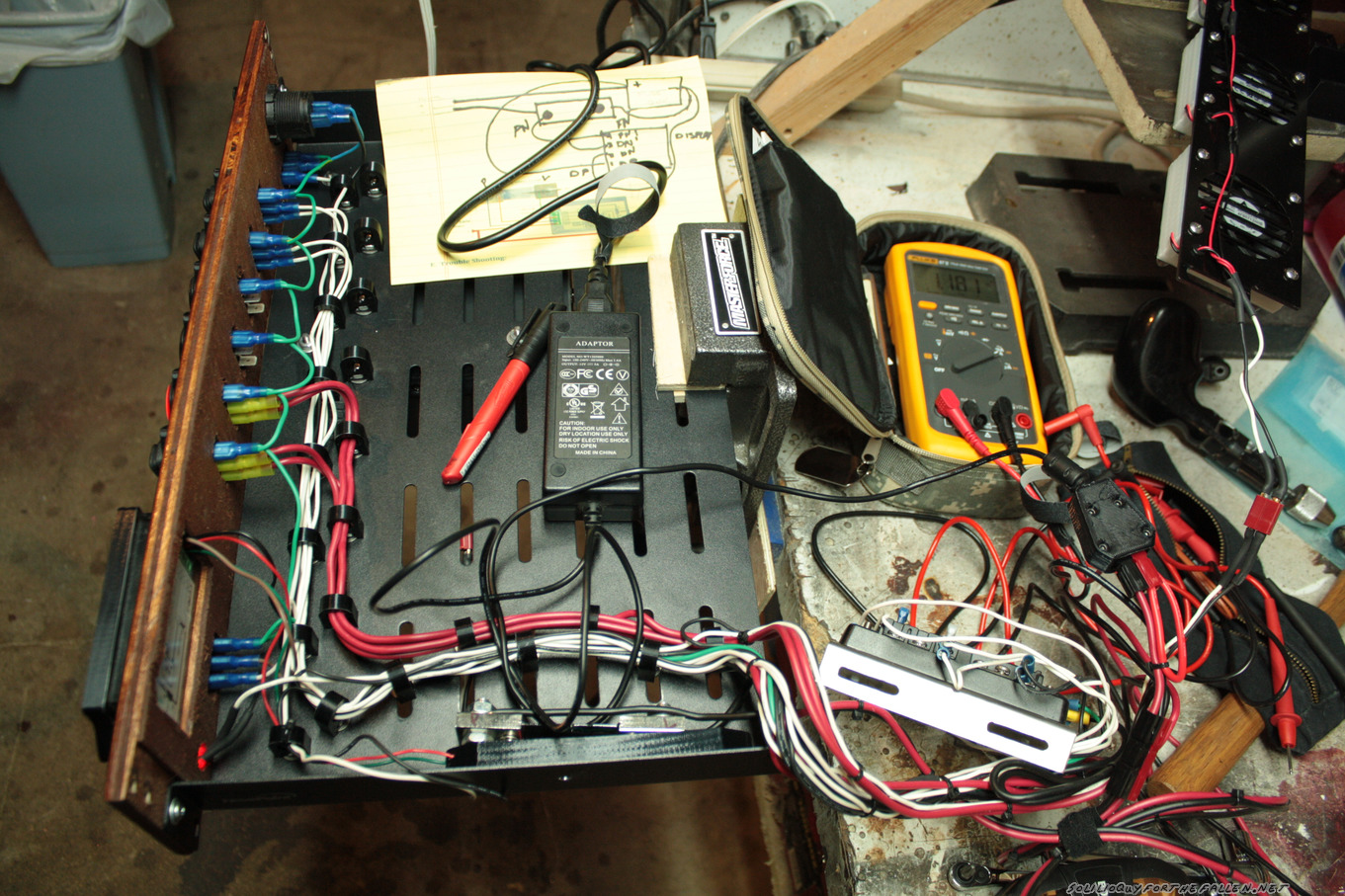

Random At The Bench

I had an issue with the amperage display reading incorrectly. Here I am verify the wire and testing its reading against my fluke 87V.

Parts

Ordered Parts

- SKB 6u Shallow Rack

- Blue Sea Systems ST Blade Fuse Block

- NavePoint 1U Racks

- Switches

- PowerSupply

- DC Shunt Monitor

- 12V Warm White LED Strip Lights

- 18 Gauge Stranded Hookup Wire, White

- 18 Gauge Stranded Hookup Wire, Black

- Deans Connectors

- Shrink Tubings

- Case Fans

- 90° PL-259 to straight PL-259 cable

- 90° UHF adapters

- Rubber Grommets

Printed Parts

Note: I have chosen to provide many of the solid model STLs for the 3D Printed Parts I used. 3D Printing is an incredible technology, and I amazed to be able to use it so easily. However, I provide these STLs without support. I may have suggestions or warnings but they are provided as is. I hope that they are useful to you, but they may not be.

- Switch Plates

- Wire Guides. Note – max capacity is 4 12 gauge automotive wires. A 8-32 x 7/16″ bolt will rack these perfectly with no interference to the wires with a .050″ fender washer and a 14 gauge steel shelf.

- DC Shunt Box STL’s

- Fan Sleeve

- Fan Cover

- Tuner Mounting Fixtures

These STL’s are licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License. I do not certify anything other then loosing your beer money over these. They may or may not be useful. Remember, only Hu can Prevent Florist Friars!

Is a very good presentation. Lots of work put in it.

I would advise to use shelves that have lip on rear and/or front. Those used will sag some.

I prefer metal panels. And why all the switches, and controls??? Most not needed.

I also like metering of the AC and DC supplies and LED indicators to indicate both a supply is connected and it is on or off. Make sure all like lighting and fans work on 12VDC so all will work no matter the power source.

I find most Go Boxes with this gear will fit nicely in 4u high case. One issue when making these boxes is will it need to be transported like to a Field Day or EOC event??? If so size and weight are an important issue. Even if light if big it is hard to handle.

Thanks!

You’re right, these shelves have already began to sag some. Metal is nice, but I can’t work with it as effectively as I can with wood. I agree that most of the switches are not needed, but I’ll leave this shack-in-a-box as it is. The fans & lights are rated to run on 12V and run from the onboard power mains, which I can connect to any supply set for 13.8v. I was using an old PSU from a computer but will be putting a samlex in soon.

I will your suggestions in mind for Mk 2 – like many other points that you made.

Going with a 6u was to future proof this as a shack-in-a-box. Its not to bulky that I can’t transport it if needed.

[…] a previous post, I documented the build process of my ham shack in a box. Notably lacking was a power source to […]