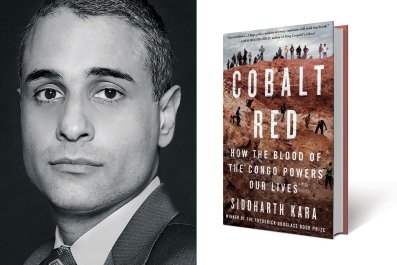

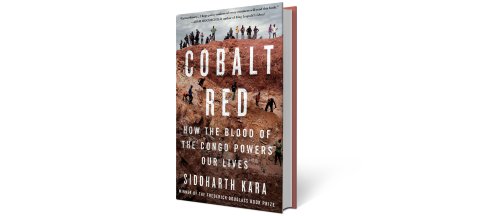

The Copper Belt in the Congo (DRC)—a 250-mile crescent from Kolwezi to northern Zambia—is the source of 10 percent of the world's copper as well as about half of the world's cobalt reserves. Cobalt—deemed "critical" by the European Union and "strategic" by the United States—is essential for all of today's rechargeable batteries, from smartphone and laptop batteries to e-bikes and electric vehicles, which require up to 22 pounds of refined cobalt each, more than 1000 times that required for a smartphone battery. In addition to its use in batteries, the mineral is used in turbines, dental surgeries, chemotherapy, missile guidance systems and more. Demand for the resource is expected to grow by almost 500 percent by 2050, and only in the DRC does so much of the valuable mineral exist. To extract cobalt in the DRC, side-by-side with authorized industrial mining operations, are hundreds of thousands of "artisanal" miners, the vast majority of which operate outside any authorized mining areas or safety protocols. These men, women and children miners are subjected to harsh conditions and low wages, and it is they who are the subject of Siddharth Kara's new book, Cobalt Red (St. Martin's Press, January), from which the following excerpt comes.

The Kipushi artisanal mining area was located in an open swath of earth just south of the abandoned Gécamines company pit. It was a vast lunar wasteland spanning several square miles—a bizarre juxtaposition to the advanced Kipushi Corporation (KICO) mining compound sitting right next to it. KICO had first-world mining equipment, excavation techniques and safety measures. The artisanal site seemed to be time-warped from centuries before, populated by peasants using rudimentary tools to hack at the earth. More than 3000 women, children and men shoveled, scraped and scrounged across the artisanal mining zone under a ferocious sun and a haze of dust. With each hack at the earth, a puff of dirt floated up like a specter into the lungs of the diggers.

As we walked along the periphery of the site, my local guide Philippe reached down and handed me a stone about twice the size of my fist. "Mbazi," he said. Heterogenite. I studied the stone closely. It was dense with a rugged texture, adorned with an alluring mix of teal and azure, speckles of silver and patches of orange and red—cobalt, nickel, copper. This was it. The beating heart of the rechargeable economy. Heterogenite can come in the form of a large stone, such as the one Philippe handed to me, as smaller pebbles or weathered down into sand. Cobalt is toxic to touch and breathe, but that is not the biggest worry that the artisanal miners have. The ore often contains traces of radioactive uranium.

I dropped the stone and followed Philippe deeper into the mining area. Most of the artisanal miners cast suspicious glances as I walked by. A teenage mother stopped digging and leaned against her shovel under the murky daylight. She gazed at me as if I were an invader. Dust swallowed the meager infant strapped to her back, head cocked at a right angle to its fragile body. Philippe asked if she would be open to speaking with us. "Who will fill this sack while I talk to you?" she responded angrily. We walked farther through the mine and found a group of six males caked in dirt and mud, ages 8 to 35.

"Jambo," Philippe greeted the group, the Swahili word for "hello."

"Jambo," they replied.

The group was digging inside a 16-foot-deep pit about 20 feet wide. The younger boys dug with small shovels closer to the surface, while the men dug deeper into the claylike sediment. The bottom of the pit was submerged in about a foot of copper-colored water. The oldest member of the group was Faustin. He was lean and hardened, with a face compressed toward the center. He wore plastic slippers, olive trousers, a light tan T-shirt and a baseball cap.

Faustin explained that he, his brother, brother-in-law, wife, cousin and three children worked in a group. "We work with the people we trust," he said. Each day, they filled large raffia sacks with mud, dirt and heterogenite stones that they dug out of the pit. They broke down larger stones into pebbles using a metal mallet so that they could fit more into each sack. Once the sacks were full, they carried them to nearby pools of water to sift the contents through a kaningio (metal sieve). The sieved heterogenite stones were then loaded back into the sacks. It took several such cycles each day to obtain enough heterogenite pebbles to fill one large raffia sack.

"By the end of one day, we can produce three sacks of heterogenite," Faustin explained. "We take them over there near KICO. The négociants (traders) come to that place. We sell the cobalt to them [and then] they transport the sacks to the comptoirs (depots) and sell it to them."

"Why don't you take the cobalt to the depots yourself?" I asked.

"I don't have a motorbike. Some other creuseurs (diggers) can do the transportation to the comptoirs themselves, but this is a risk, because you must have a permit to transport ore in Congo. If the police find us when we are transporting the ore without the permits, we will be arrested," Faustin explained.

I asked what kind of permit was required. Faustin was not sure of the details, only that it was too expensive for most artisanal miners. Philippe filled in the details. "There are three different permits required for trans- porting ore. The price depends on how much ore is being transported and the distance it is transported."

The ore transportation fees seemed to be little more than a money grab by the government. Why else charge people for driving rocks from one place to another? The fees also made it impossible for most artisanal miners to access markets directly due to their inability to pay the tax. Being cut off from the marketplace forced them to accept submarket prices from négociants for their hard labor, further reinforcing the state of poverty that pushed them into artisanal mining to begin with.

I asked Faustin and the members in his group about their health. They complained of persistent coughs and headaches. They also suffered minor injuries such as cuts and sprains, as well as back and neck pain. None of them wanted to come to the artisanal mining area to dig each day, but they felt they had no choice.

"What I can tell you is there is no other work for most people who live here," Faustin said. "Yet anyone can dig cobalt and earn money."

I worked through the arithmetic of just how much the members of Faustin's group were able to earn. The eight individuals in the group produced on average three sacks of washed heterogenite ore per day, and each sack weighed an average of 88 pounds. The négociants that came to the site paid 5,000 Congolese francs per sack, or about $2.80. This payment implied an income of roughly $1.05 per team member per day. The heterogenite in Kipushi had a cobalt grade of 1 percent or less, which was much lower than the heterogenite closer to Kolwezi, where cobalt grades could exceed 10 percent. The low grade of cobalt in Kipushi had a direct bearing on the meager incomes earned by the artisanal miners who worked in the area.

After I finished speaking with Faustin's group, two of the boys, André and Kisangi, 8 and 10 years old, offered to demonstrate the sieving process. I followed them from the pit as they dragged a raffia sack bursting with dirt and stones. It probably weighed more than they did. After about 100 feet, we arrived at a washing pool that was used by several groups of artisanal miners. The pool of water was a putrid, bubbly, copper-colored swamp.

The boys tipped the sack over and emptied the contents by hand into a large pile next to the washing pool. André stepped bare-skinned into the noxious water and picked up the copper-colored metal sieve by two handles at one end. He lodged the other end of the sieve into the dirt at the edge of the pool. Kisangi used a small, rusted metal shovel to scoop the contents of the sack onto the sieve. André then vigorously yanked the sieve up and down through the surface of the water, separating dirt from stone. His tiny shoulders looked as if they would pop out of their sockets with each jolt. After a few minutes, only pebbles remained in the sieve. André appeared exhausted and barely managed to hold the sieve above water while Kisangi scooped the pebbles out by hand and placed them in a pile. The children would repeat this arduous process another 10 or 15 times to sieve all the stones from the sack, and they had to sieve several sacks each day.

"Our mother and sister pick up the stones and put them in that bucket," Kisangi explained. "They use the bucket to fill another sack with these stones."

Philippe and I left the rinsing pool and walked farther into the artisanal mining area over rolling craters and shifting shades of brown. An oppressive haze hung in the air. There were no trees to be found and no birds in the sky. The earth had been stripped bare as far as the eye could see. It seemed as if half the teenage girls at the site had infants strapped to their backs. Boys as young as 6 took wide stances and summoned all the strength in their bony arms to hack at the earth with rusted spades.

Somewhere close to the border with Zambia, or perhaps just on the other side, I came across several young women dressed in sarongs and T-shirts, standing in shallow pits with about 6 inches of coppery water at the bottom. They were not kin to each other but worked in a group to keep safe. Sexual assault by male artisanal miners, négociants, and soldiers was common in mining areas. The women said they all knew someone who had been shoved into a pit and attacked, the likely cause of at least some of the babies strapped to teenage backs. The women and girls who suffered these attacks represented the invisible, brutalized backbone of the global cobalt supply chain.

A young woman named Priscille stood in one of the pits with a plastic bowl in her right hand. She rapidly scooped dirt and water with the bowl and flung it onto a sieve a few feet in front of her. Her motions were precise and symmetrical, as if she were a piece of machinery designed only for this purpose. After the sieve was filled with gray-colored mud and sand, Priscille yanked the sieve up and down until only the sand remained. That sand contained traces of cobalt, which she scooped with her plastic bowl into a pink raffia sack. I asked Priscille how long it took her to fill one sack with the sand.

"If I work very hard for 12 hours, I can fill one sack each day," she replied.

At the end of the day, the women helped each other to haul their 110-pound sacks just over half a mile to the front of the site where négociants purchased each from them for around $0.80. Priscille said that she had no family and lived in a small hut on her own. Her husband used to work at this site with her, but he died a year ago from a respiratory illness. They tried to have children, but she miscarried twice.

"I thank God for taking my babies," she said. "Here it is better not to be born."

By evening, I finished the last interview and made my way back to the front of the artisanal mining area near the edge of the KICO compound. I was expecting to see a team of formal mineral traders, perhaps with government uniforms or badges, but instead, the négociants were young men dressed in jeans and casual shirts. Unlike the dirt-crusted artisanal miners, their clothes were clean and bright. Most of the négociants arrived on motorbikes along with a few pickup trucks, which they used to transport the sacks to the depots. There were hundreds of white, blue, orange and pink raffia sacks stacked next to the artisanal miners. The négociants took a cursory look inside the sacks and offered a fixed price that the artisanal miners had to accept. Philippe told me that women were always paid less than men for the same sack of cobalt.

"For this reason, the only women you will see selling the cobalt are the ones who work on their own," he explained.

One négociant, Eli, said that prior to being a négociant, he used to sell mobile phone top-up minutes for Africell in Lubumbashi, but his cousin convinced him to obtain authorization to be a négociant. The fee was $150, and it had to be paid annually.

"Now I make two or three times in a day what I used to make," Eli said. I asked if I could see what the authorization document looked like.

"It expired two years ago!" Eli replied.

"What happens if a police officer asks to see your permit when you are transporting minerals?"

"We pay a fine. Maybe 10 dollars, but this does not happen often."

After speaking to a few more négociants, I wandered back into the mining area to take a final look before darkness fell. A lone girl stood atop a dome of dirt, hands on her hips, eyes cast long across the barren land where giant trees once ruled. Her gold-and-indigo sarong fluttered wildly in the wind as she surveyed the ruin of people and earth. Beyond the horizon, beyond all reason and morality, people from another world awoke and checked their smartphones. None of the artisanal miners I met in Kipushi had ever even seen one.

▸ Adapted from Cobalt Red,published by St. Martin's Press. Copyright © 2023 by Siddharth Kara.

Correction 1/25/23 7:06 am ET: A misspelling in the author's name has been corrected.