Abstract

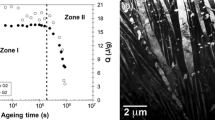

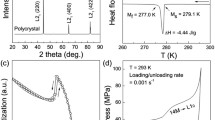

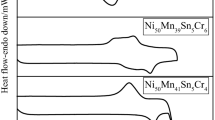

This work investigates the effects of time dependency for isothermal sintering on additive manufactured Ni–Mn–Ga magnetic shape memory alloys. Binder jetting additive manufacturing was used to produce Ni–Mn–Ga parts from pre-alloyed powders. Additive manufacturing via the binder jetting technique produces parts with intrinsic porosities, based on the morphology of the source material. The Ni–Mn–Ga parts printed in this study using the binder jetting method possessed average densities of ~ 46% before sintering. These samples were sintered at 1353 K in increments of 10 h up to 50 h. Based on this temperature and time frame, (1) microstructural evolution, (2) crystallographic phase analysis, (3) transformation behaviors, and (4) thermal–physical properties were investigated. The additive manufactured Ni–Mn–Ga samples exhibited increases in densities, from ~ 74 to ~ 83% due to solid-state diffusion mechanisms. X-ray diffraction reveals that all of the additive manufactured samples have the 5 M martensitic phase at room temperature. Reversible martensitic transformation temperatures were recorded during heating and cooling cycles through differential scanning calorimetry, which indicate austenitic phase transformations occurring slightly above ambient temperatures. Additionally, analysis of the heating and cooling cycles prescribes that the entropy and Gibb’s energies decrease over the reversible martensitic transformations as sintering time increases. It is envisioned that this study will support a more synergistic manufacturing process between binder jetting additive manufacturing and post-heat treatment processes for Ni–Mn–Ga shape memory alloys.

Similar content being viewed by others

Explore related subjects

Discover the latest articles and news from researchers in related subjects, suggested using machine learning.References

Chernenko VA, Besseghini S (2008) Sens Actuators Phys 142:542–548

Ullakko K, Huang JK, Kantner C, O’Handley RC, Kokorin VV (1996) Appl Phys Lett 69:1966–1968

Sozinov A, Likhachev AA, Lanska N, Ullakko K (2002) Appl Phys Lett 80:1746–1748

Lagoudas DC (2008) Shape memory alloys: modeling and engineering applications. Springer, Berlin

Faran E, Shilo D (2016) Exp Tech 40:1005–1031

Shiva S, Palani IA, Mishra SK, Paul CP, Kukreja LM (2015) Opt Laser Technol 69:44–51

Krishna BV, Bose S, Bandyopadhyay A (2007) Metall Mater Trans A 38:1096–1103

Xiong F, Liu Y, Pagounis E (2005) J Magn Magn Mater 285:410–416

Roth S, Gaitzsch U, Pötschke M, Schultz L (2008) Adv Mater Res 52:29–34

Chmielus M, Zhang XX, Witherspoon C, Dunand DC, Müllner P (2009) Nat Mater 8:863–866

Caputo MP, Berkowitz AE, Armstrong A, Müllner P, Solomon CV (2018) Addit Manuf 21:579–588

Caputo MP, Solomon CV (2017) Mater Lett 200:87–89

Utela BR, Storti D, Anderson RL, Ganter M (2010) J Manuf Sci Eng Trans ASME 132:110081–110089

Liu J, Rynerson M (2003) Method for article fabrication using carbohydrate binder, US6585930 B2

Do T, Kwon P, Shin CS (2017) Int J Mach Tools Manuf 121:50–60

Mostafaei A, Rodriguez De Vecchis P, Stevens EL, Chmielus M (2018) Acta Mater 154:355–364

Li Y, Xu F, Hu X, Dong B, Luan Y, Xiao Y (2016) Materials 9:132

Bai Y, Williams CB (2015) Rapid Prototyp J 21:177–185

Witherspoon C, Zheng P, Chmielus M, Dunand DC, Müllner P (2015) Acta Mater 92:64–71

Dunand DC, Müllner P (2011) Adv Mater 23:216–232

Banhart J (2001) Prog Mater Sci 46:559–632

Castaño FJ, Nelson-Cheeseman B, O’Handley RC, Ross CA, Redondo C, Castaño F (2003) J Appl Phys 93:8492–8494

Zheng P, Kucza NJ, Patrick CL, Müllner P, Dunand DC (2015) J Alloys Compd 624:226–233

Richard M, Feuchtwanger J, Schlagel D, Lograsso T, Allen SM, O’Handley RC (2006) Scr Mater 54:1797–1801

Righi L, Albertini F, Calestani G, Pareti L, Paoluzi A, Ritter C, Algarabel PA, Morellon L, Ricardo Ibarra M (2006) J Solid State Chem 179:3525–3533

Righi L, Albertini F, Pareti L, Paoluzi A, Calestani G (2007) Acta Mater 55:5237–5245

Righi L, Albertini F, Villa E, Paoluzi A, Calestani G, Chernenko V, Besseghini S, Ritter C, Passaretti F (2008) Acta Mater 56:4529–4535

Pons J, Chernenko VA, Santamarta R, Cesari E (2000) Acta Mater 48:3027–3038

Jiang C, Muhammad Y, Deng L, Wu W, Xu H (2004) Acta Mater 52:2779–2785

Sánchez-Alarcos V, Pérez-Landazábal JI, Recarte V, Rodríguez-Velamazán JA, Chernenko VA (2010) J Phys Condens Matter 22:166001

Heczko O, Lanska N, Soderberg O, Ullakko K (2002) J Magn Magn Mater 242(Part 2):1446–1449

Sofronie M, Tolea F, Kuncser V, Valeanu M (2010) J Appl Phys 107:113905

Wu SK, Yang ST (2003) Mater Lett 57:4291–4296

Sánchez-Alarcos V, Recarte V, Pérez-Landazábal JI, Cuello GJ (2007) Acta Mater 55:3883–3889

Singh RK, Shamsuddin M, Gopalan R, Mathur RP, Chandrasekaran V (2008) Mater Sci Eng A 476:195–200

Tian B, Chen F, Tong Y, Li L, Zheng Y (2012) J Mater Eng Perform 21:2530–2534

Tian B, Chen F, Liu Y, Zheng YF (2008) Mater Lett 62:2851–2854

Kök M, Aydogdu Y (2012) Thermochim Acta 548:51–55

Jiang C, Feng G, Gong S, Xu H (2003) Mater Sci Eng A 342:231–235

Ma Y, Jiang C, Li Y, Xu H, Wang C, Liu X (2007) Acta Mater 55:1533–1541

Palazzo P (2012) Int J Energy Environ Eng 3:4

Acknowledgements

The authors would like to acknowledge the use of the facilities within the Center for Excellence in Materials Science and Engineering and Center for Innovation in Additive Manufacturing at Youngstown State University. MPC and DRW gratefully acknowledge the financial support provided by the Engineering Technology and Commonwealth Engineering (ETCE), Pennsylvania State University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors hereby declare, to the best of their knowledge, that all relationships and/or interests of the manuscript do not include a conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Caputo, M.P., Waryoba, D.R. & Solomon, C.V. Sintering effects on additive manufactured Ni–Mn–Ga shape memory alloys: a microstructure and thermal analysis. J Mater Sci 55, 5311–5321 (2020). https://doi.org/10.1007/s10853-020-04352-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-04352-9