Latest News

Events, Community

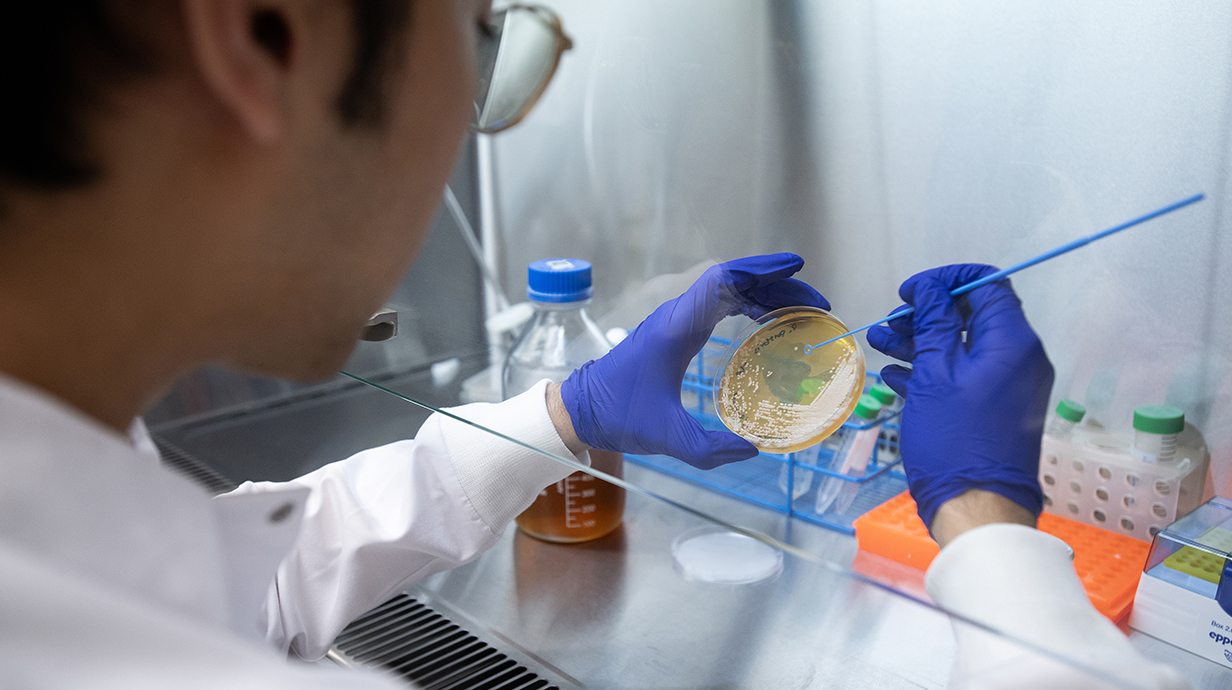

Ole Miss Opens Its Doors for a Day of Discovery and Fun

OXFORD, Miss. – The University of Mississippi campus will be all abuzz with activities April 12 as it hosts its annual Mississippi Day. This ultimate outdoor open house will celebrate and showcase the opportunities the flagship offers.